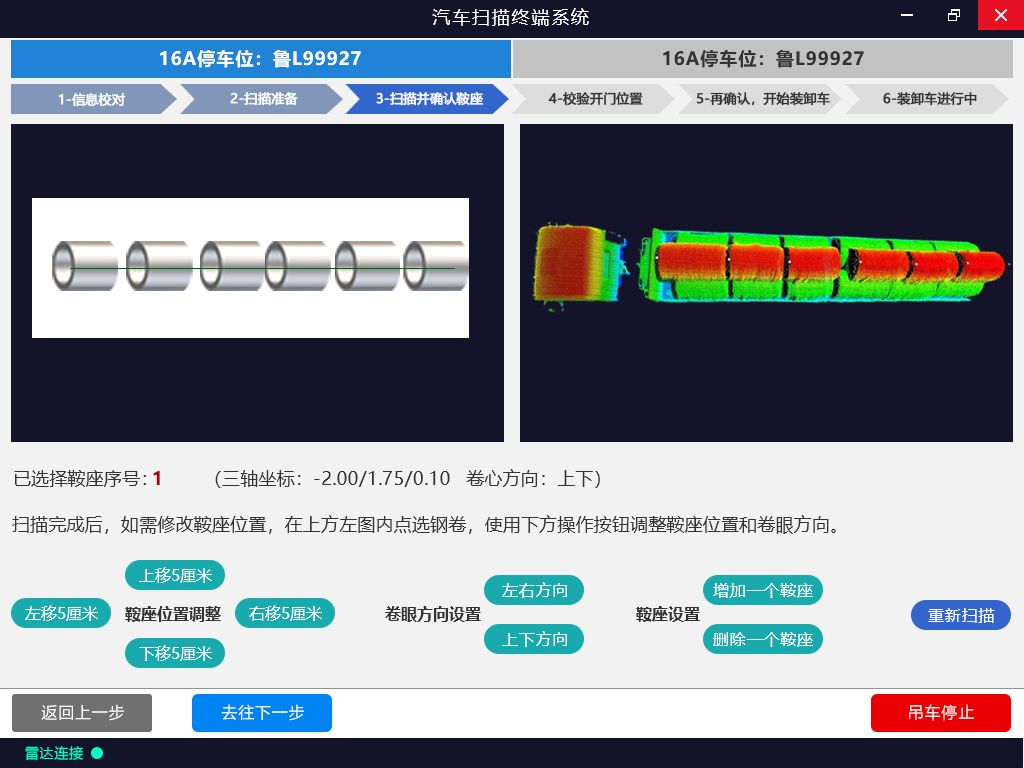

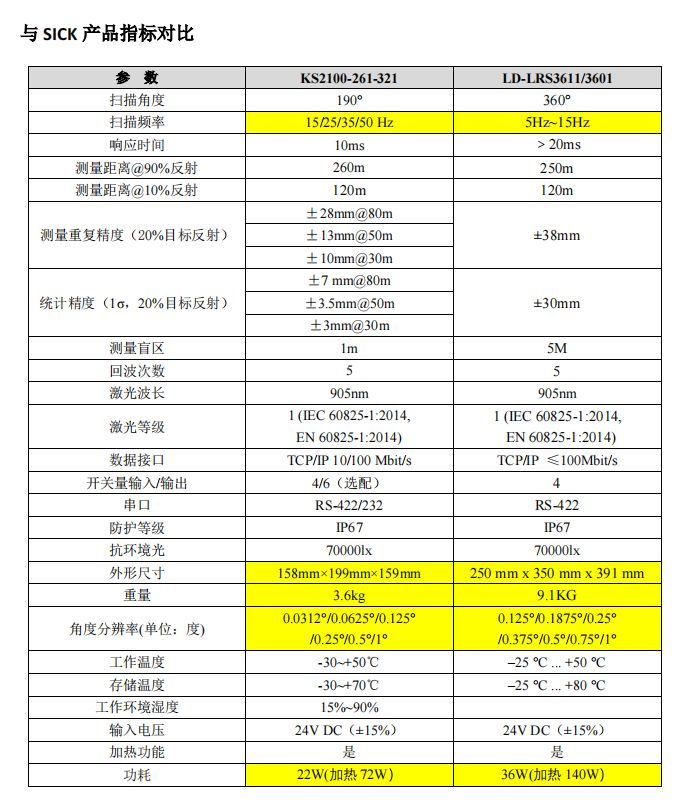

When loading the car, use a 3D pan/tilt and laser scanner to scan the empty car to obtain the coordinates of each point in the car. After placing a layer of coils in the car, a second scan is performed to give the shape of the material after the materials have been loaded in the car. , and the coordinates of each point for driving to stack the two-layer coils. When unloading the car, use a 3D pan/tilt and laser scanner to scan the existing coils in the car to obtain the coil outline shape and the centerline coordinates of the highest point of each coil. After unloading the second layer of coils, scan again to obtain The outline shape of the first layer of coils and the centerline coordinates of the highest point of each coil. In this system, Party B provides laser scanning equipment selection and software customization.

This project is a laser scanning acquisition system that collects and extracts data for empty cars, coil scanning and unloading coil scanning to meet the management system's requirements for the warehouse area.